Industry: Lighting

Product Innovation Journey: THINK CREATE APPROVE BUILD CARE

Services: StrategyMechanical designElectronics designProductionTesting and validationCertification

Industry: Lighting

Product Innovation Journey: THINK CREATE APPROVE BUILD CARE

Services: StrategyMechanical designElectronics designProductionTesting and validationCertification

beMatrix is a renowned producer of modular exhibit stands and has been a leader in event solutions for many years. One of their key products, the SAM Light, is used to illuminate exhibit setups, providing essential lighting to enhance visual displays. With solutions that integrate LED walls, lighting, and other technologies seamlessly, beMatrix has become a key player in the event and exhibition industry, constantly pushing the boundaries of what modular stands can achieve.

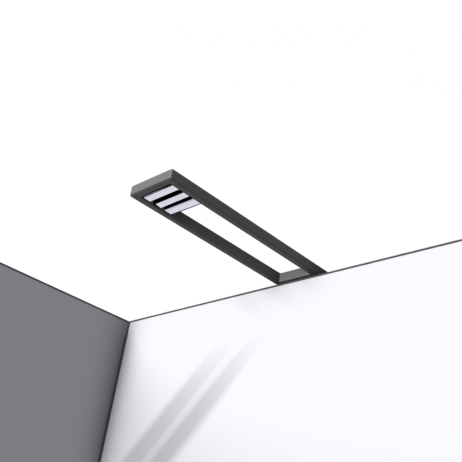

However, the product initially lacked the flexibility and functionality needed for modern exhibitions. To address this, beMatrix partnered with Alberic for a full redesign, transforming the SAM Light into a more adaptable and customizable lighting system, including the ability to independently control each of its three LED bars and provide both warm and cool white light.

In the THINK phase, we thoroughly assessed the SAM Light’s existing design and identified areas for improvement. beMatrix sought more control over light temperature and directionality, while also increasing the durability of the product to handle frequent use in event settings. Our team conducted an in-depth analysis, focusing on the technical aspects of how the lighting could be improved for better performance and more versatility in different environments.

In the CREATE phase, we completely re-engineered the product’s mechanical and electronic components. The key advancement in this phase was enabling each of the three LED bars to rotate independently—a capability that was not present in the original design. This was made possible through the integration of CPC lenses, which could be swapped out to adjust the beam angles (40°, 60°, or 120°), giving users flexibility for various setups. Additionally, we optimized the cooling system to ensure that the LED bars could rotate freely without overheating, adding a thicker rear plate for enhanced stability.

On the electronics side, we developed a custom driver to switch between warm and cool light modes, meeting beMatrix’s need for more adaptable lighting solutions. We also added the ability to link up to six SAM Light units in a daisy-chain configuration, depending on the available power supply, making the system scalable for larger exhibitions.

In the APPROVE phase, we ensured that the redesigned SAM Light met all necessary certifications. Our in-house team managed the CE certification, while also assisting beMatrix with the UL certification process in Italy, ensuring compliance with international standards for safe and reliable use in exhibitions worldwide.

In the BUILD phase, we transitioned to high-volume production. Alberic handled both prototyping and mass production of the SAM Light, using injection molding to ensure high-quality, cost-effective manufacturing. The lights were assembled, packaged, and shipped directly from our facility to beMatrix’s distribution centers.

Finally, in the CARE phase, we continue to support beMatrix post-launch, ensuring that the SAM Light remains reliable and continues to perform at its best. We provide ongoing maintenance and technical support, ensuring that beMatrix can confidently rely on us for future product improvements and expansions.

To this day, five years after the start of the project, the SAM Light is still produced at Alberic, showcasing the longevity and success of our collaboration.